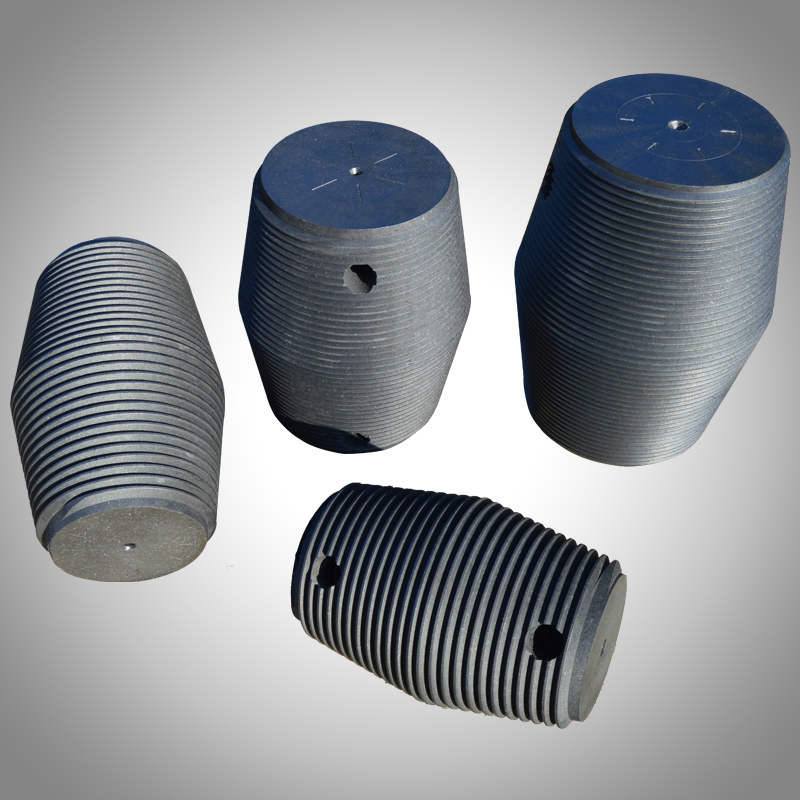

1. Cylindrical nipple, cylindrical nipple processing is relatively simple and high processing efficiency, even if the cylindrical nipple is loosened due to vibration and will not fall back immediately, the connection thread can be continued to use after 2 to 3 turns of the back thread, the disadvantage is the electrode The wall thickness of the two nipples is the same inside and outside, the overall strength of the nipple hole is small, it is easy to swell, and the expansion stress generated by the nipple is easy to burst.

Protecting the cylindrical nipple into the electrode nipple hole is difficult, and it usually takes about 10 turns to tighten.

2. Conical nipples, conical nipples require higher processing technology and lower processing efficiency than cylindrical nipples. When using a conical connector, the electrode and the connector can be tightened by only 2 to 3 turns after the connector extends into the electrode connector hole.

However, if the processing accuracy is poor, the tightening torque is insufficient, and the nipple is loosened after vibration, as long as it is pulled back 2 to 3 times, the nipple or the lower electrode will fall. The biggest advantage of the conical connector is that the longitudinal section of the hole wall of the electrode connector is tapered (thin outer wall and thick inner wall), the overall strength is large, and it is not easy to be swollen, the middle diameter of the nipple is large, and it is not easy to be broken (or Break).

The use of conical nipples, such as the addition of nipple bolts, can reduce the phenomenon of loosening of the connection parts or the nipple being pulled off (or broken). During the steel-making process, the lower end of the electrode is formed into a cone due to oxidation and slag washout. When using a cylindrical nipple, the nipple residue on the end of the electrode cone is easy to fall, which increases the electrode consumption.

When using a conical nipple, the geometry of the nipple is a double cone, which is not easy to drop. Products of basically the same quality, the general power large-size graphite electrodes use conical nipples and are equipped with nipple bolts. The consumption of graphite electrodes per ton of electric furnace steel can be reduced by 10% to 15% compared with the use of cylindrical nipples.

Therefore, most of the large and medium-sized graphite electrodes produced by carbon factories at home and abroad in the 1980s process conical nipples, and a few carbon factories are still processing cylindrical nipples.

Post time: Jun-19-2020